MASTERSOUND FACTORY VISIT

Luciano Sanavio

MastersounD today has the new and largest headquarters in the province of Vicenza, Arcugnano, and it is made by people ready to seize new challenges united by the same profound passion of Cesare Sanavio.

The brand has existed since 1994 (and is about to surpass the milestone of 30 years), but, as we will discover, it draws its roots from a much more distant past....

It took the hand of Antonio Ferro, the new CEO (and owner of the Esperienze Audio store), to bring the MastersounD brand into the right commercial and communication cords.

This is what visits to the company are for, among a thousand other things! The production headquarters is just a stone's throw from Sonus Faber, and the journalist wonders: I've been here a hundred times and never noticed, even though the consoling thesis is that the anonymous shed, far from the aesthetic splendors of Sonus Faber, wouldn't have caught your eye anyway. And you even doubt: Sonus faber, Pathos, Unison Research, Viva, and also MastersounD, all in a kind of technological triangle with Vicenza as the epicenter: we absolutely must investigate the red thread that unites them...

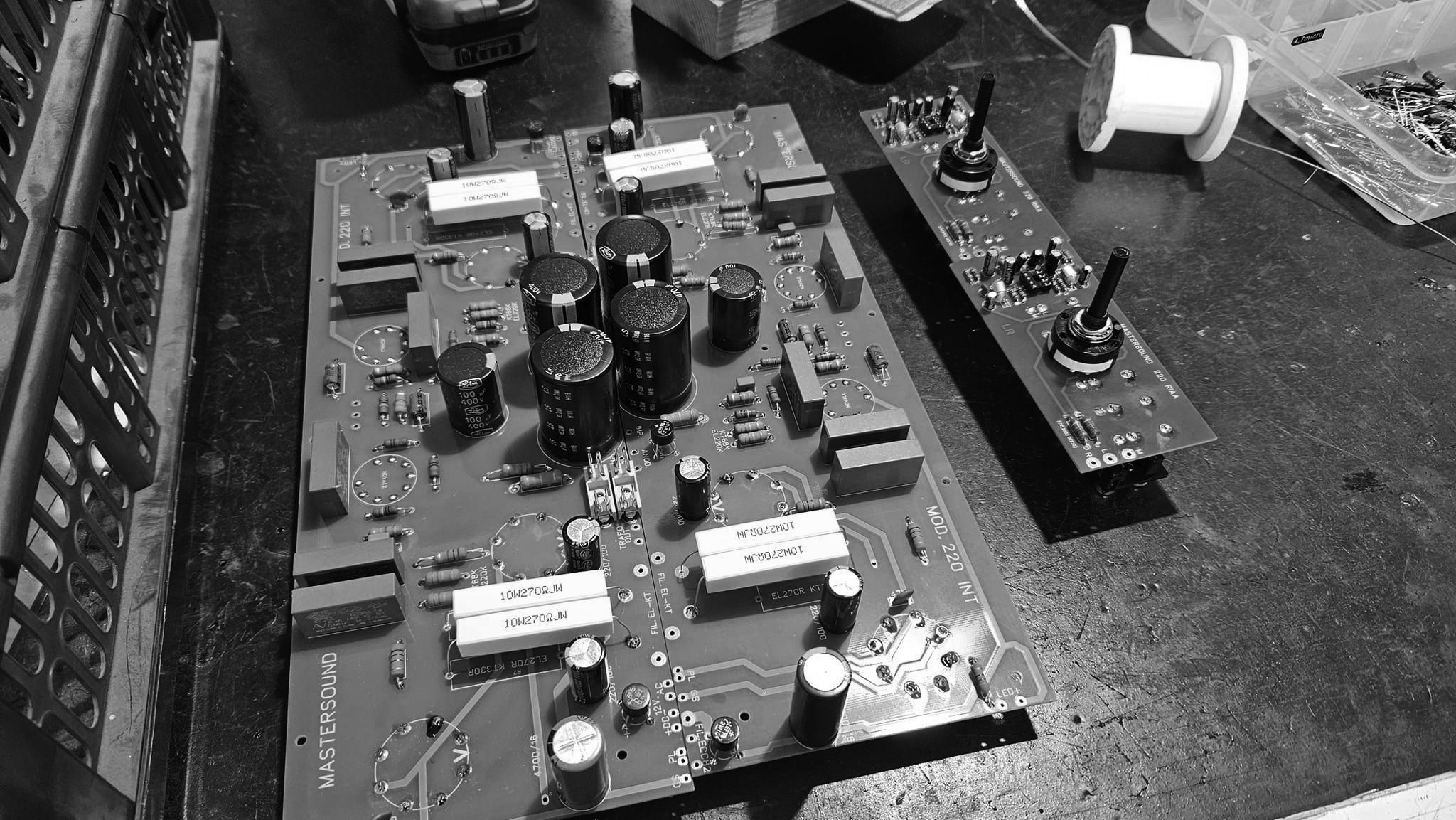

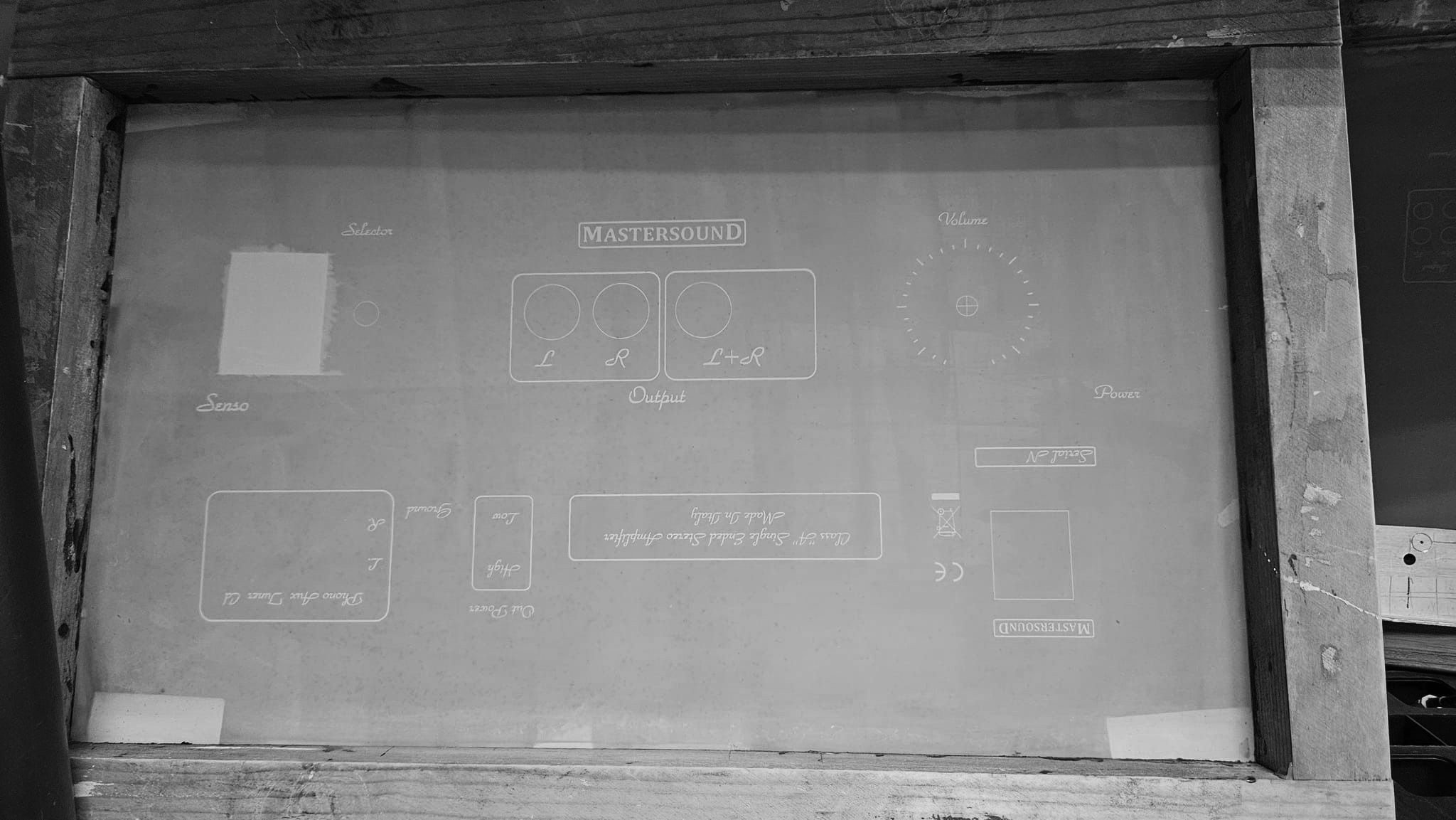

So, here we are crossing the entrance of the MastersounD factory, and we say factory in the full sense of the term because here the products of the company, all handmade, are truly built from scratch. We immediately discover that the anonymous appearance outside does not correspond to what we find inside, which has been shaped as needed and immediately betrays the artisanal dimension of the company: "Here there are 100 thousand tools. Luciano Sanavio (editor's note) if something is missing, he makes it, and even if something is bought, he always modifies it...". As we delve into the process, the truly Teutonic order that replaces the usual chaos of places like this is striking. Even the machine for winding the coils of the output transformers, which must be somewhat dated, looks immaculate: there is a Litz wire because "at the moment we are making PF 100 (a 120W Class A power amplifier) that has the output transformer in Litz..."

Yes, the output transformer, the essential component when it comes to tube amplification, an essential element to understand who MastersounD is... And we must take a leap back in time to the 1950s when Cesare Sanavio graduated as an electronics technician with a thesis on output transformers in tube amplifiers. We are in the TV boom, and the American company he worked for sent Sanavio to travel through South America: Brazil, Chile, and Paraguay, where the entire family settled.

"My father," recounts Luciano Sanavio, who has now taken over the reins of design, "was also involved in the design and installation of audio systems (initially amplified by tube systems) for churches and shops (and we even built brothels!). At the age of 12, my father had already started building electronics. In wartime, he was already building clandestine radios to listen to broadcasts. He studied at the State Industrial Technical Institute A. Rossi: he made the first oscilloscope, which is still in the museum of the Rossi Institute, the MUST.

He could listen to a circuit just by looking at it! When we moved to South America, he worked as a designer for other companies; so, we went to a country where he had to start TV factories, still in black and white and initially with tubes, and once they were established, they moved to another country until we arrived in Paraguay, which we liked as a country, and we settled there! The first brand was called Telesound: I remember going to Argentina to a company called Luxury to buy components because they were not available in Paraguay."

But then you returned...

We are from Vicenza, and we returned to Vicenza, where we were still involved in design, and where, at some point, he obviously gave up and left everything to me. We started producing output transformers, and shortly after, Unison contacted us, which at that time had design problems. It started like this: transformers and designs for others. We worked for almost all the major Italian tube manufacturers, and through Vaic Valve, we were the first to make them: when these tubes arrived, no one wanted to touch them because the manufacturers had made science fiction about these tubes, then someone tried them, and they shattered into a thousand pieces! We found the right parameters and produced the first Vaic, which were the 52 B with Mr. Kron, who had also settled in Vicenza and managed the company. Then we also made products for Ayon, which, with the same Vaic tubes, had meanwhile changed its name.

Certainly, Vicenza for some reason has been a kind of Italian technological hub...

I think it's thanks to the early days of Unison Research, which with tubes generated astonishment and stirred the waters quite a bit. When they started making the Simply Two, they sold a monstrous quantity in the East, and that was their fortune; those first tube amplifiers made us known all over the world. Even Amedeo Schembri, before founding Viva, used to consult with my father, and they would conduct experiments. We made a lot of output transformers for transistors that were 8 ohms. We used to meet frequently with him. After that, the Germans and Austrians came, and Gerhard Hirt arrived, commissioning us to produce Vaic. Then a Chinese came, I don't remember his name, who asked us to produce stainless steel devices for him to distribute in the East: inside the device, if one opened it, there was a board marked MastersounD!

So, did the MastersounD brand come before MastersounD products?

No, we started selling finished products in parallel. We were still in a garage on the other side of Vicenza and had opened a small workshop, starting to make our first prototypes and the various 52Bs.

How was the name decided?

I was the architect, I threw it out there: my brother and I were having lunch with my father, and we decided it there. We had imagined another logo, half white and half black, but then architect Alessandro Costanzia di Costigliole arrived, an industrial designer and partner of BluARCH, a design studio in Milan; he is very important and famous, he won the Compasso d'Oro, (Industrial design award) and he made the current logo...

And where can MastersounD go?

This is a trick question! I am not an audiophile, I don't invent or color sounds, I just want performance: my goal is to continue developing this!

Are there still possibilities for improvement?

Oh my goodness, of course: every time I intervene, I discover something new! Practically, today's electronics has nothing to do with electronics from twenty years ago! Output transformers are completely different from how they were made in the past. In fact, we can bring out the bass, the speed. In a 20-watt amplifier, an output transformer that retains 90% efficiency allows for a remarkable sound level, such that many do not believe it is such a low-power amplifier, but it is only speed and control over the speaker. We don't use the classic output transformer with very thin wire and many turns to achieve the required impedance. For us, few turns, thick wire, and we play on the construction to recover the impedance.

We use Litz wire only for the PF 100 for performance reasons, and I have to say that it's already too much for me; with normal copper, I almost prefer it because with our calculations, with our systems, we have no problems with bandwidth. I don't need to have thin and long wires: thick wire throws out current and low resistance; the speaker moves but stops when it wants to; the fine wire, which is resistive, throws current into the transformer instead of being controlled by the transformer. This was the discovery that emerged at MastersounD about thirty years ago, working and experimenting on the output transformer. Ours are very simple, much simpler than traditional transformers, and, above all, they reduce the stress on the tube a lot, and the tube in pure Class A, which has to last 2,000 hours, normally far exceeds that. My 300B still works and has the same original tube!

The output transformers generally on the market have been designed for more than fifty years and always remain with those formulas. No one develops them, no one does anything. The transformer must be developed more than anything else. For each tube that arrives, we make a custom transformer. When they write to me and ask, "Can I also mount KT88 or KT120 on this amplifier?" I tell them that technically, it can be done, but it's not the same thing!

Let's take a flight of fancy: MastersounD has incredible success worldwide, and you find yourself having to think about its growth. In that scenario, would you say, "Now it's someone else's turn because my dimension is that of being a craftsman," or does the challenge tempt you, where from a craftsman, you have to become a company?

Certainly, it tempts me: I don't intend to give up; on the contrary, my head is full of ideas, and the computer is full of projects. I have experimented with and discovered many things, like new transformers we made for the Booster 150 or a completely revolutionary transformer system that is a 2-in-1 transformer. Instead of making a Push-Pull, I made two primaries...

The powerful Mastersound Compact 845 removes the requisite for high-efficiency speakers and bucks the ‘pipe and slippers’ SET stereotype by balancing seductive, tubey lushness with ballsy, dynamic punch.

Richard Barclay - THE EAR MAGAZINE